If you close your eyes and picture a "factory," what do you see?

Do you see steam, grease, manual levers, and hundreds of workers standing along a conveyor belt tightening bolts? If you do, your vision is about twenty years out of date.

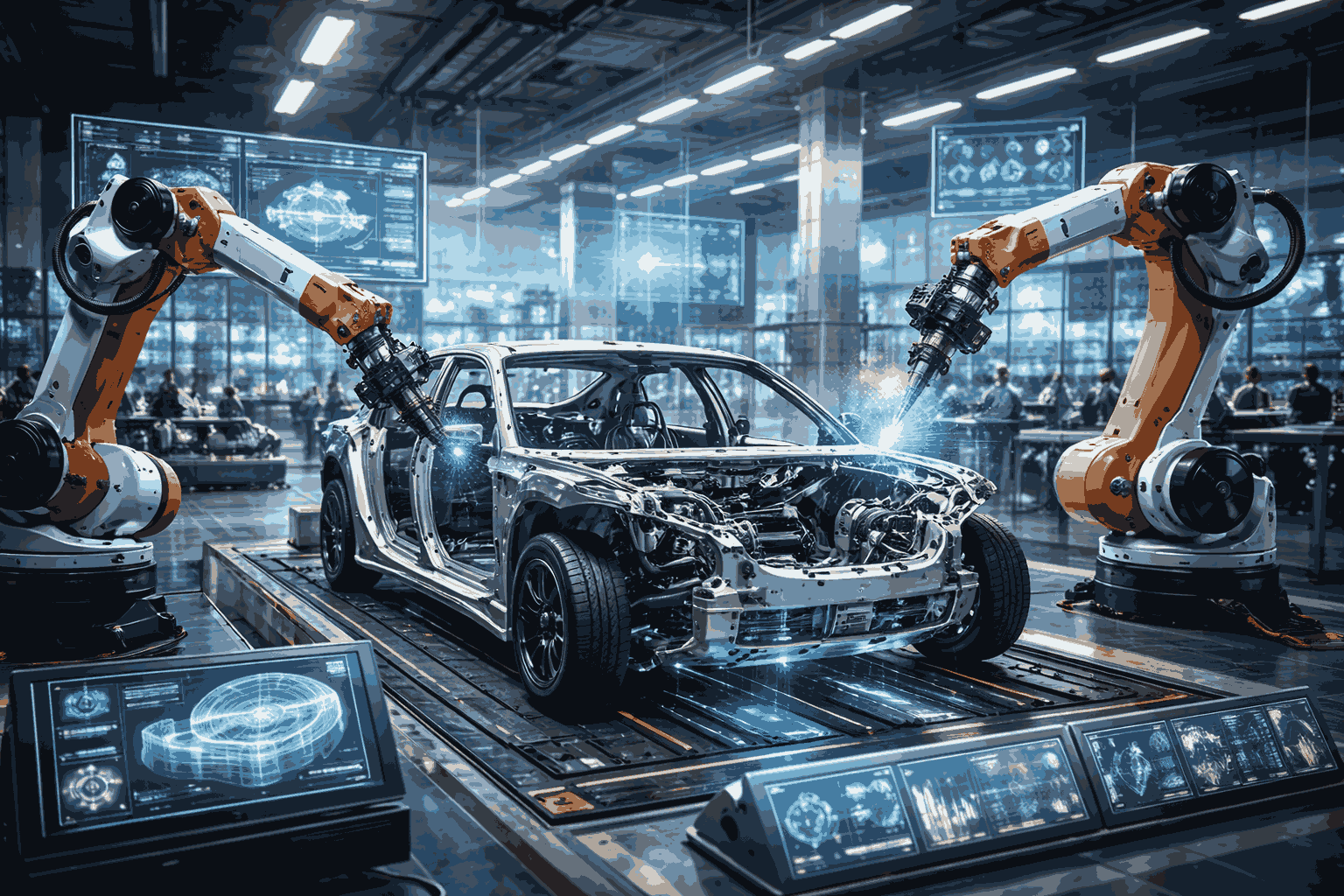

The modern automotive plant has undergone a silent revolution. Walk into a facility like the Suzuki Motor Gujarat plant today, and you won't just see machines; you will see an ecosystem. Robots talk to conveyors; sensors talk to servers; and the entire production line adjusts itself in real-time based on data.

This is Industry 4.0. It is the era of the "Smart Factory."

For engineers, this shift is both a threat and an opportunity. The traditional role of the "Shift Engineer" who walks the floor with a clipboard is disappearing. In its place, a new role is emerging: the Smart Manufacturing Engineer.

If you are looking for a Manufacturing course that prepares you for 2026 and beyond, you need to understand that the rules of the game have changed. Here is why the factory of the future requires a completely new toolkit.

1. The Death of "Dumb" Machinery

In the past, a stamping press was a "dumb" machine. It went up and down until it broke or a human turned it off.

Today, that same press is an IoT (Internet of Things) device.

- It has vibration sensors that predict bearing failure weeks before it happens.

- It monitors energy consumption in milliseconds.

- It uploads production data to the cloud instantly.

This means a Manufacturing Engineer can no longer just be a "Mechanical" guy. You need to understand Data Acquisition. You need to know how to read the dashboard that tells you why the machine is slowing down, not just how to fix it with a wrench.

2. The Rise of the "Digital Twin"

One of the most disruptive technologies in Smart Factories is the concept of the Digital Twin.

Before a physical car is ever built, or a physical production line is ever assembled, a virtual replica is created in software.

Engineers run simulations on this "Digital Twin" to test scenarios:

- “What happens if we increase the conveyor speed by 5%?”

- “Will the robot arm collide with the pillar if we change the welding angle?”

This allows companies to solve problems before they even spend a rupee on steel.

For an aspiring engineer, this means skills in simulation software and virtual commissioning are now just as important as reading a blueprint. If you cannot operate in the virtual world, you cannot manage the physical one.

3. Automation is the New Literacy

The heart of the Smart Factory is Automation. We are not just talking about a single robot; we are talking about Integrated Automation.

This is where the skills gap is widest. Employers are desperate for engineers who possess industry automation training in three specific areas:

- PLC (Programmable Logic Controllers): The brain of the factory. You need to know how to write the logic that tells the machine what to do.

- SCADA (Supervisory Control and Data Acquisition): The nervous system that gathers data from hundreds of sensors and presents it to the operator.

- HMI (Human Machine Interface): Designing the screens that allow humans to control these complex beasts safely.

If your resume says "Knowledge of Manufacturing" but you don't know what a PLC Ladder Logic is, you are at a massive disadvantage.

4. Robots: From Cage to Collaboration

Robotics has also evolved. We are moving from dangerous, caged industrial robots to Cobots (Collaborative Robots) smart bots that work alongside humans safely.

Programming these robots requires a mix of spatial awareness and coding skills. It is no longer enough to use a teach pendant; modern engineers program robots using offline simulation tools to optimize their path and cycle time to the millisecond.

5. Why a Traditional Degree Isn't Enough

The problem with a standard B.Tech or even a generic mtech in automotive engineering is the lag time. University labs are expensive to update. Most colleges are still teaching automation using kits from the early 2000s.

But the industry uses technology that was released last year.

This is why iACE exists. Our Centre of Excellence is built in partnership with Maruti Suzuki to mirror a live production environment.

- Real Hardware: You train on industrial-grade KUKA and Fanuc robots, not educational toys.

- Live PLCs: You program the actual Siemens and Mitsubishi PLCs used in factories worldwide.

- The "Why," Not Just the "How": We teach you to design the automation logic, not just push the start button.

6. The Salary Premium

Why should you learn this? Because "Smart" skills pay "Smart" salaries.

A traditional Production Engineer is often viewed as an operational cost. An Automation Engineer or a Smart Factory Specialist is viewed as a strategic asset.

Companies pay a premium for people who can:

- Reduce downtime using predictive maintenance.

- Increase throughput using robotic optimization.

- Digitize manual processes to save cost.

This is the difference between a job that pays ₹25,000/month and a career that starts at ₹50,000/month.

Conclusion: Don't Just Run the Machine. Program It.

The factory isn't disappearing; it is upgrading. The engineers who refuse to upgrade with it will be left behind, managing legacy systems in dying industries.

But for those who embrace the shift who learn to speak the language of data, robots, and logic, the future is incredibly bright.

Don't settle for being a cog in the machine. Become the architect of the system.

Step into the future of manufacturing at iACE.

Build the factory of the future.