When we admire a luxury car, the first thing we notice is often the "Finish" that deep, mirror-like gloss that seems to glow under the streetlights. But few people realize that achieving that perfection is one of the most chemically complex processes in manufacturing.

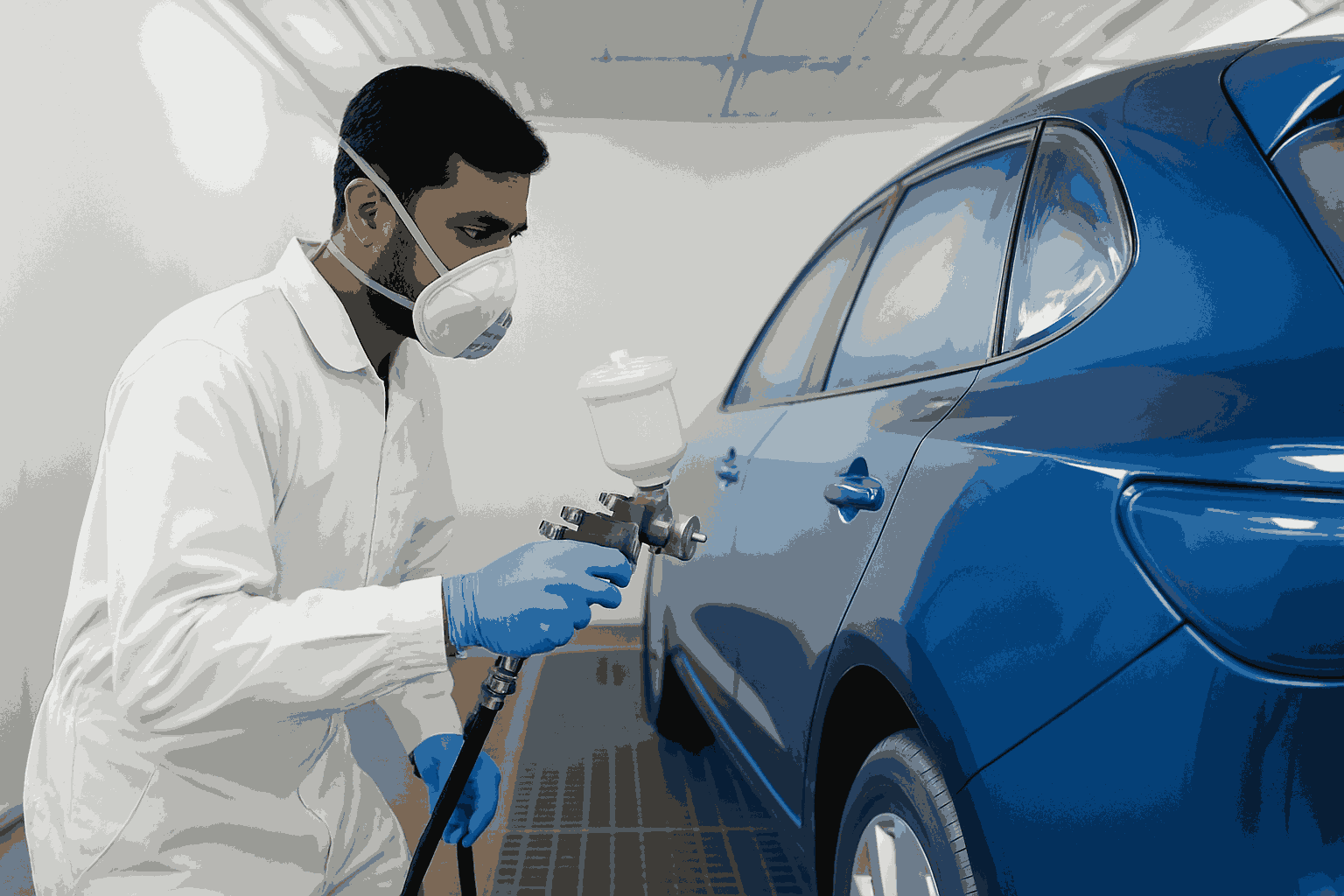

Automotive painting has evolved far beyond a spray can and a mask. Today, it is a convergence of fluid dynamics, electrostatics, and robotics. For aspiring technicians, enrolling in a specialized automotive painting course is the first step toward understanding that this is not just an art; it is a rigorous science.

The industry is moving away from manual estimation to digital precision. Here is why the modern paint shop is more like a laboratory than a garage, and why the demand for skilled "Paint Technologists" is rising.

The 100-Micron Engineering Feat

A standard automotive paint job is thinner than a human hair (roughly 100-120 microns), yet it must withstand UV radiation, acid rain, stone chips, and extreme heat for decades.

To achieve this, manufacturers use a multi-layer system that technicians must master:

- Electro-Deposition (E-Coat): The car body is dipped in an electrically charged tank to prevent rust.

- Primer: The smoothing layer that hides imperfections.

- Base Coat: The actual color, often containing mica or metallic flakes for that “sparkle.”

- Clear Coat: The protective armor that gives the gloss.

Understanding how these chemicals bond at a molecular level is crucial. If the humidity in the booth is off by even 5%, the solvent won't evaporate correctly, leading to defects like "orange peel" or "solvent pop."

Robots and Humans: The Collaborative Booth

While robots handle the heavy lifting of painting the main body, the human eye is still the ultimate quality control tool. However, the human role has shifted.

Technicians today need to understand Electrostatic Spraying. This is a technique where the paint particles are charged with high voltage (up to 60kV) so they are magnetically attracted to the grounded car body. This wraps the paint around corners, reducing waste.

Operating this equipment requires training that goes beyond a standard automotive certification course. You need to know how to program the robot’s path, adjust the fluid flow rate, and maintain the high-voltage electrostatic bells.

The Color Match Challenge

Have you ever tried to match the paint on a scratched bumper? It’s a nightmare. This is because modern colors are "living" formulas.

Advanced paint technicians use Spectrophotometers digital cameras that analyze color wavelengths to find the exact match. They don't just mix red and blue; they adjust the "flop" (how the color looks from the side) and the "face" (how it looks head-on).

This mix of digital colour theory and manual skill is a rare commodity. It transforms a painter into a highly paid specialist.

Why Certification Matters?

In the past, painters learned by trial and error. Today, paint materials are incredibly expensive. A liter of premium automotive basecoat can cost thousands of rupees. No workshop can afford a technician who learns by making mistakes.

This is why employers demand recognized qualifications. A structured automobile certification courses credential proves that you understand safety protocols (handling isocyanates), environmental regulations, and defect analysis.

At iACE, our Paint Technology Center is built in partnership with industry leaders like Maruti Suzuki and Kansai Nerolac. We don't just simulate the process; we have a fully functional paint booth where students work with real industry-grade consumables.

Conclusion

The "Finish" is the first thing a customer sees and the last thing they remember. Being the person responsible for that perfection is a career of immense pride and potential.

Don't treat painting as a hobby. Treat it as the science it is. If you have the eye for detail and the drive to master the technology, explore the specialized paint programs at iACE. Turn your passion for colour into a brilliant career.