For decades, the image of an automotive factory was intimidating: sparks flying, massive robotic arms swinging behind yellow safety cages, and humans standing far away to avoid injury. That era is ending.

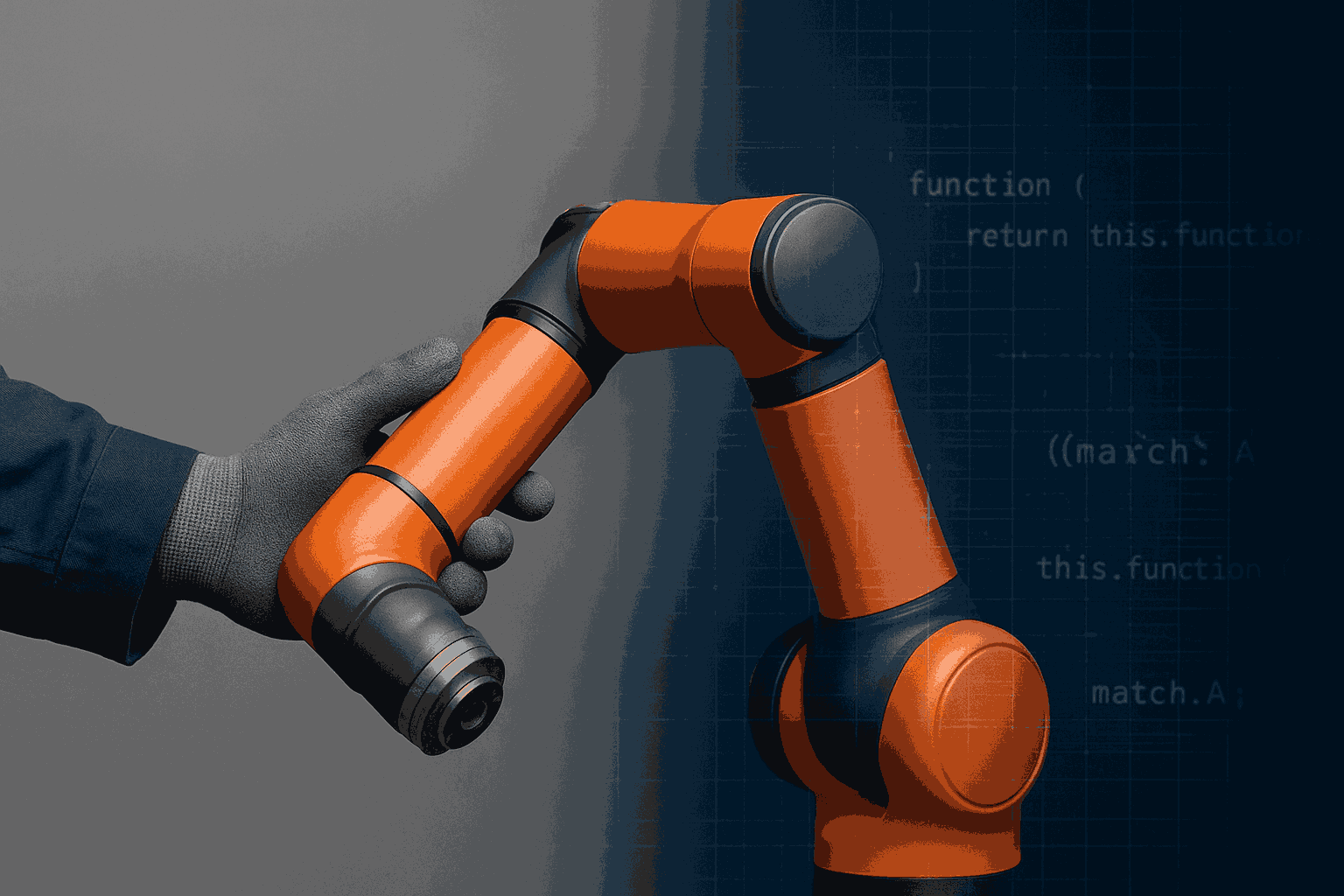

The new standard is Industry 4.0, and its defining character is the "Cobot" or Collaborative Robot. Unlike their dangerous predecessors, cobots are designed to work alongside humans, not replace them. They are uncaged, sensor-laden, and smart.

But here is the paradox: The more automated our factories become, the more valuable the human touch becomes. Automation isn't removing the worker; it is upgrading them. Here is how collaborative robots are transforming the floor and why the demand for specialized industry automation training is higher than ever.

What is a "Cobot"? (And Why It Matters)

Traditional industrial robots are strong but "dumb." If you walk into their path, they won't stop. Cobots, however, are equipped with advanced torque sensors and cameras. If they feel unexpected resistance like bumping into a technician’s arm, they freeze instantly.

This safety allows for a hybrid workflow. A robot can handle the heavy lifting (like holding a 20kg dashboard in place) while a human technician performs the delicate wiring work. This partnership increases efficiency by up to 85% compared to humans or robots working alone.

However, these machines don't run themselves. They require a new breed of professional who understands programming, sensor calibration, and maintenance. This is where a focused robotic course bridges the gap between manual labor and engineering management.

Precision Meets Intuition

Robots are masters of repetition; humans are masters of adaptability.

- The Robot's Job: Apply sealant to a windshield with 0.1mm accuracy, 500 times a day without getting tired.

- The Human's Job: Inspect the glass for microscopic flaws, adjust the robot’s path for a new car model, and troubleshoot if the sealant pressure drops.

In this ecosystem, the human isn't just a button-pusher; they are the "pilot" of the manufacturing cell. This shift has turned the factory floor into a high-tech lab. To succeed here, professionals need a comprehensive Manufacturing course that covers more than just assembly lines, it must teach the integration of digital systems and physical hardware.

The Skill Gap: Who Will Run the Machines?

The biggest threat to the automotive industry right now isn't a lack of technology; it's a lack of talent. Manufacturers are desperate for staff who have undergone industry automation training.

They don't just need PhDs in robotics. They need:

- Technicians who can teach a cobot a new movement path using a handheld tablet (teach pendant).

- Supervisors who understand the data flow between the robot and the factory’s central computer (IIoT).

- Maintenance Staff who can fix a servo motor before it halts production.

If your resume only shows traditional mechanical skills, you are at risk of obsolescence. But if you add "Robotic System Integration" to your skillset, you become future-proof.

Experience Industry 4.0 at iACE

Theory is useless without practice. You cannot learn to program a robot from a textbook.

At the International Automobile Centre of Excellence (iACE), our Manufacturing Systems program is built around this reality. We don't just talk about automation; we have active labs where students work with the same industrial-grade robots used by major OEMs like Maruti Suzuki.

Our curriculum is designed to take you from the basics of pneumatics and hydraulics all the way to advanced PLCs (Programmable Logic Controllers) and SCADA systems. Whether you are taking a short-term robotic course to upskill or a full-year Post Graduate Program, the goal is the same: Job Readiness.

Conclusion

The "Lights Out" factory (a factory with zero humans) is a myth. The future of automotive manufacturing is collaborative. It is a future where humans provide the creativity and judgment, and robots provide the strength and precision.

The question isn't whether robots will take your job. The question is: Will you be the one trained to control them? Equip yourself with the right skills today by exploring the Manufacturing course options at iACE.