For the last decade, the career conversation has been dominated by "Software." Everyone wanted to code apps, manage servers, or analyze data. Meanwhile, the art of making things, the physical hardware that keeps the world moving was quietly undergoing a revolution.

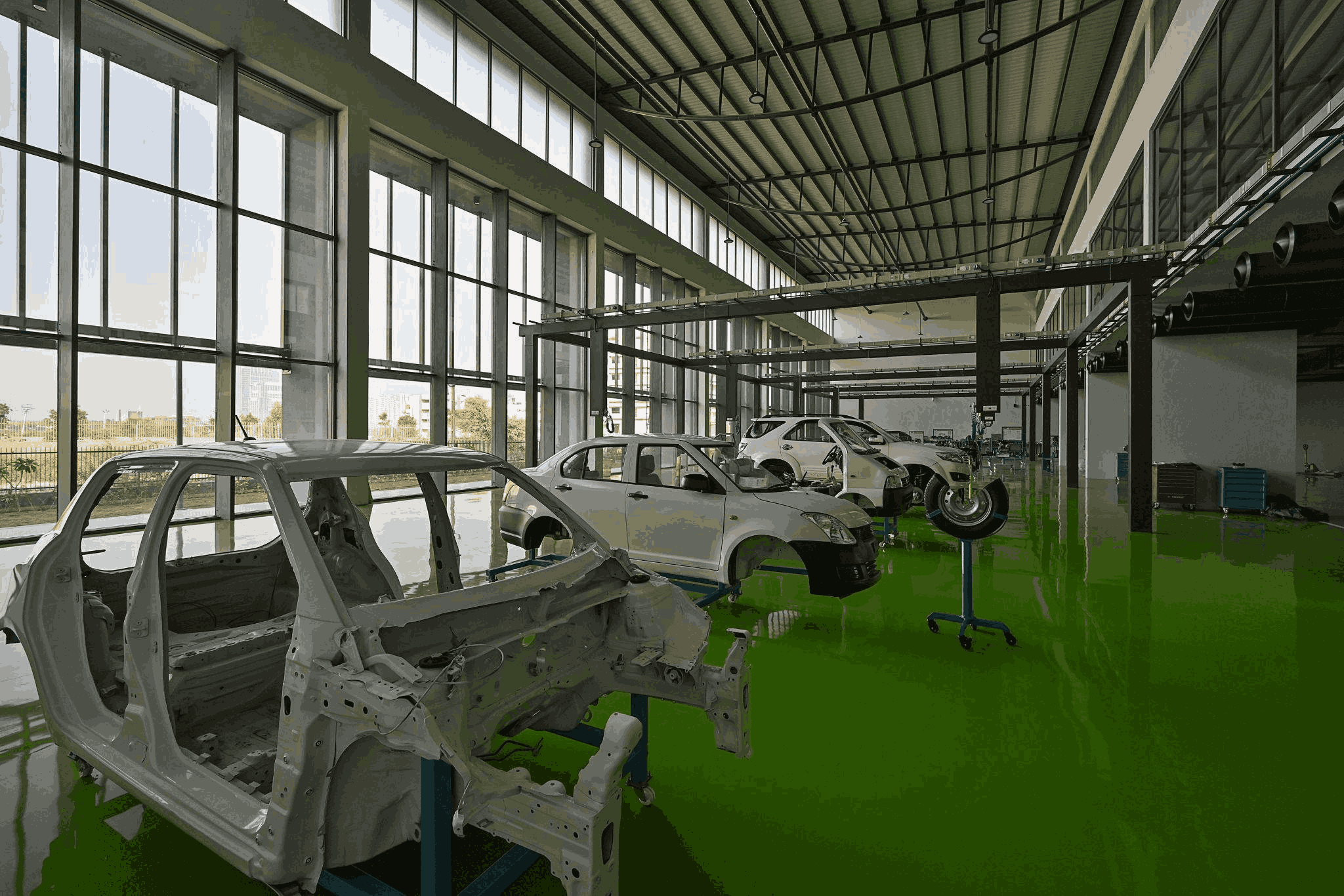

Today, we are witnessing a massive resurgence in high-tech manufacturing. As vehicles become more complex and safety standards become stricter, the "General Mechanic" is being replaced by the "Specialist Technician."

The industry is facing a severe shortage of skilled professionals who can handle the sub-millimeter precision required for modern automobiles. Here is why specialized technical skills are the new currency of the job market and why specialized short-term courses are your fastest route to a premium salary.

1. CNC: The Digital Sculptors

Gone are the days of manual lathes and guesswork. Modern manufacturing is driven by Computer Numerical Control (CNC). A cnc course today isn't just about operating a machine; it is about bridging the gap between digital design (CAD) and physical reality.

In the automotive sector, engine components, transmission gears, and EV motor casings require tolerances measured in microns (thinner than a human hair).

- The Skill: It involves programming, setting up multi-axis machines, and understanding metallurgy.

- The Demand: Every Tier-1 supplier feeding companies like Maruti Suzuki or Tata Motors needs certified CNC experts who can ensure zero-defect production.

2. Injection Molding: Shaping the Future (Literally)

Look inside any modern car. The dashboard, the door panels, the center console, and even lightweight engine parts, it is all advanced polymer technology.

As Electric Vehicles (EVs) push for lighter weight to increase range, the reliance on high-quality plastic components is skyrocketing. This has created a massive demand for professionals who understand injection molding.

An injection molding course at iACE teaches you the science behind the art. It’s not just about melting plastic; it’s about understanding flow dynamics, mold design, temperature control, and material science. This is a niche field with very few qualified experts, making it a high-growth career path.

3. Welding: The Safety-Critical Skill

Welding is often misunderstood as a basic trade. In reality, automotive welding is a highly sophisticated, safety-critical process. Whether it is the chassis of a car or the battery cage of an EV, a single weak weld can be catastrophic.

This is why generic knowledge is no longer enough. The industry demands standardized, verifiable skills specifically, a welding certification course recognized by global bodies.

At iACE, our partnership with the American Welding Society (AWS) ensures that our students aren't just learning to join metals; they are learning international standards of quality, safety, and testing. From robotic spot welding to manual TIG welding for exotic alloys, certification is the passport to global opportunities.

The iACE Advantage: Industry-Grade Training

Why do students struggle to find jobs despite having a diploma? The answer is usually "Outdated Skills." Learning on a machine from 1990 does not prepare you for a factory in 2025.

The International Automobile Centre of Excellence (iACE) solves this with our Advance Certification Programs (ACP).

- Real Machinery: You train on the same industrial robots and CNC units used by Maruti Suzuki.

- Short Duration, High Impact: These courses are designed for speed. In just a few months, you gain a specialization that sets you apart from the crowd.

- Focus on Employability: We don't just teach you the "How"; we teach you the "Why," making you ready for the troubleshooting challenges of a real shop floor.

Master the Art of Making

The world will always need software, but software needs hardware to run on. The people who build that hardware with precision, skill, and expertise are the backbone of the economy.

If you enjoy working with your hands but want a career that offers growth, respect, and technical challenge, it is time to specialize. Whether it is the digital precision of a CNC course, the material science of molding, or the structural integrity of welding, your future is waiting to be built.

Don't settle for being a generalist. Become a specialist. Visit iACE today and choose the skill that will define your career.